Contract Electronics Manufacturing

Quality. Punctual deliveries. Ad hoc solutions.

Focused on contract electronics manufacturing since day 1, we are experts and we provide quality, punctuality and tailor-made electronic solutions.

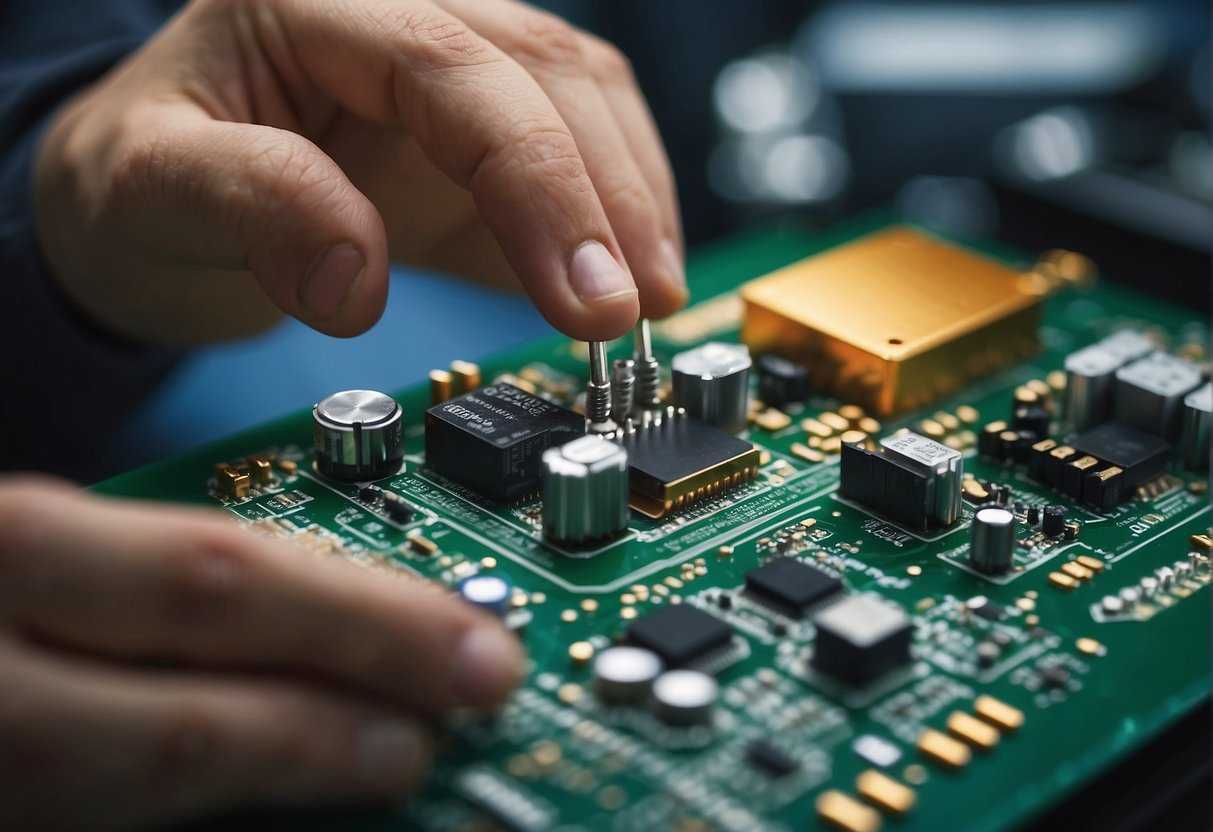

Our company has always specialised in the production of electronic boards for a variety of sectors and fields of application. Thanks to our experience and know-how built up over the years, we are the ideal partner for the production of quality boards in the world of industrial electronics.

Our expertise extends to all stages of production, guaranteeing optimal and customised solutions: from purchasing components from reliable and established sources, to assembly in PTH and SMT, through to functional testing of the board produced and management of batch delivery at destination.

Reliability, efficiency and flexibility are the three pillars on which we base all our production services, guaranteeing:

- quality of results

- timeliness of deliveries

- first-class electronic solutions

The main phases of electronics manufacturing, from purchasing electronic components to outbound logistics

In the electronics production process, each step is crucial to ensure high quality finished products and compliance with standards. Our commitment lies not only in managing, but also in optimising each step to ensure above-average results.

Here is a brief overview of the electronic production steps.

1. Procurement and management of electronic components

Raw material management is the first vital step in our production process. We only purchase electronic components from reliable suppliers, ensuring maximum quality and traceability. Synergy with our partners is essential to maintain high standards of safety and efficiency.

2. Preparing the production order

We prepare each production order carefully, planning resources and production times to ensure maximum flexibility and efficiency. The ability to handle urgent orders and adapt to specific requirements is a strength that has always set us apart.

3. Assembly and Welding

The assembly process is carried out using traditional (PTH - pin through hole) or surface-mounted technology (SMT - surface mounted technology). For the soldering phase, the most appropriate soldering techniques are used using a wave soldering machine or static crucible, supervised by qualified personnel.

4. Quality Control

After soldering, each board undergoes a quality check, which begins with an optical inspection and ends, as required, with an actual functional test. Safety and quality standards are paramount and we are committed to only supplying products that fully meet them.

5. Protective treatment with conformal coating

To protect electronic boards from moisture, dust and chemical stress, we apply a protective treatment known as conformal coating. This ensures greater board longevity even in the harshest environments.

6. Logistics and delivery to destination

The last step in the process is efficient logistics, with tailor-made solutions for delivery at destination. Efficient planning and logistical flexibility enable us to meet customers' deadlines with maximum punctuality.

In the production services we offer, technical knowledge translates into quality and precision that our Customers can always count on.

If you are looking for a Production Partner that can handle and assemble your electronic boards and devices, we are confident that we can amply meet your expectations, providing you with precise, punctual and concrete results.

Here are the answers to the most frequently asked questions about electronic board production.

For any information of interest to you, you can always contact us directly via the chat on the bottom right or via the contact page.

What does PCBA mean?

Is there a minimum workable batch required to start production?

What is the advantage of having a proven and robust supply chain for the procurement of electronic components?

Do you also provide electronic design services?

Would you like to receive special insights on industrial electronics?